Premium material handling components for conveyors

These material handling components are robust, durable, and boast a greater load capacity. We have combined our expertise and experience in design to ensure superior performance, precision, technology, and durability.XINGLI provides effective material handling solutions tailored to your conveying equipment or systems, product types, and loading and unloading methods.

-

-

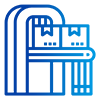

- The spring-loaded installation is one of the most commonly used methods for roller assembly due to its simplicity and ease of maintenance. It allows for quick installation and removal. The frame is secured with a tie rod to enhance structural integrity. It is crucial to maintain a 1mm clearance between the roller installation dimensions and the internal frame dimensions to ensure proper fit. The hole slot is typically 0.5mm to 1mm larger than the axle diameter, allowing sufficient space for easy roller installation.

-

-

-

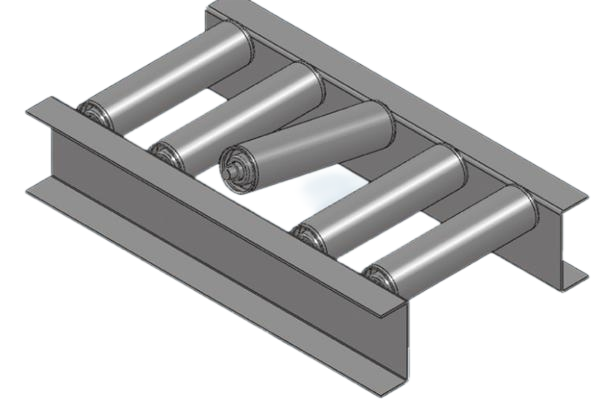

- The conveyor roller is secured to the frame using bolts at each end, eliminating the need for tie rods and enhancing the overall stability of the conveyor system. The shaft length (L) is a critical dimension in this installation type, as it determines the internal width of the frame. Typically, the shaft length is slightly smaller than the designed internal width of the frame (0~-1mm). Different shaft diameters require corresponding internal thread specifications to ensure proper fit and secure installation.

-

-

-

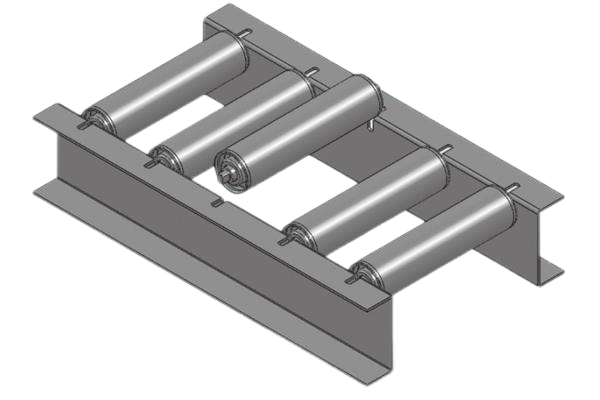

- The full flat tenon installation method is commonly used in mining roller sets. This simple installation method involves the frame having corresponding holes and slots, allowing the conveyor roller to be directly placed into the slots. For disassembly, the roller can be easily removed by lifting it out of the slots. This method is one of the simplest and most efficient installation techniques.

-

-

-

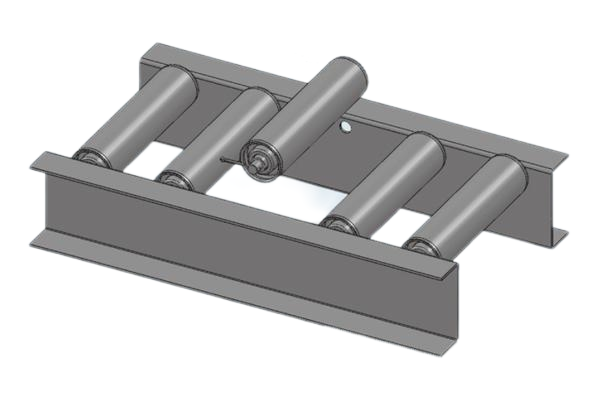

- The shaft pin hole installation method involves securing the roller to the shaft by inserting a pin into the pin hole after installation, rather than directly fixing the roller to the shaft. It is essential to maintain a 1mm clearance between the roller installation dimensions and the internal frame dimensions. To ensure easy installation, the hole slot is generally 0.5mm to 1mm larger than the axle diameter, providing sufficient space for smooth assembly.

-